PRODUCTION RAMP-UP OF A STRATEGIC VACCINE BUILDING

Nalys ensured the ramp-up of production of a strategic building for a major company in the pharmaceutical sector. The program consisted on several improvements including Cleaning In Place (CIP), Sterilization In Place (SIP) and production optimizations, mainly from process automation improvements

OBJECTIVE OF THE CUSTOMER

Increase vaccine production from one to three batches per week

A TaaS (Technology as a Service) team of up to 10 people at peak workload, was dedicated to this task.

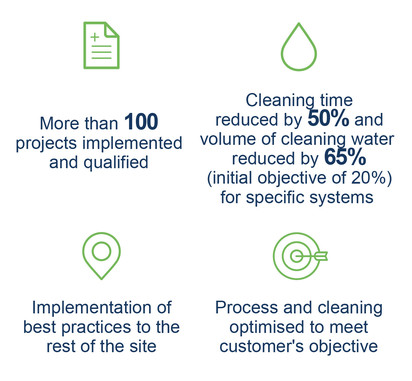

The team made up mostly of Process engineers, worked on more than 100 different projects – from small ones (<10k€) to bigger ones (>150k€) while production was still ongoing.

They worked with an integrator company under their responsibility.

PROJECT DETAILS

TECHNOLOGY & SKILLS

-

Pharmaceutical bulk production process: bioreactors, extraction vessels, chromatography skids, ultrafiltration skids, mobile vessels

-

Cleaning In Place (CIP)

-

Sterilization In Place (SIP)

-

Production optimizations, mainly from process automation improvements

-

Automation Software: Emerson DeltaV

RESULTS OF THE PROJECT

-

One team with one leader responsible for the implementation of many projects (low FTE required from client for the follow up)

-

Production capacity increased by optimization of process steps

-

Robustness increased on the process steps

-

Reduction of consumptions and increase of robustness of many CIP

-

Limited impact on production during implementation and qualification phase of the project

RESULTS OF THE PROJECT