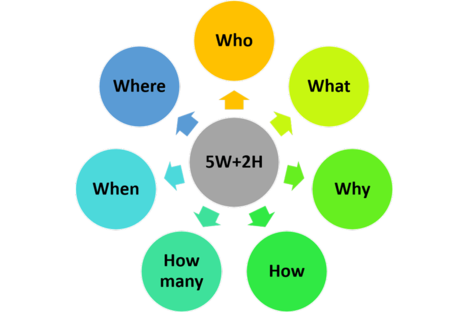

In order to demonstrate the « 5W+2H » methodology used in the pharmaceutical industry, let’s take for instance the writing of a deviation, after an event occurred.

On April 18th, 2019 the quality assurance engineer working for A&B received an email from the Chinese affiliate, to alert him about a non-conformity that has been noticed in April 11th 2019, after an audit managed by the local authorities. It appears that two batches of medicine « X », produced and commercialised since 8 months, contain the API (active pharmaceutical ingredient) « Y ». The issue is that the dossier for the addition of the API « Y » is not submitted.

By applying the « 5W+1H » tool, the deviation has been scientifically written as follow:

Who: quality assurance engineer received an email from the Chinese affiliate

What: non-conformity on 2 batches of medicine « X » containing API « Y »

Where: China (Chinese affiliate of A&B)

When: date receipt email: 18/04/2019 - date of detection: 11/04/2019

Why: dossier for the addition of the API was not submitted

How: during an inspection by the Chinese authorities

How many: two batches

A step we could add to this tool: « Why do that? »

This last notion, not mentioned previously, is an element that turns out to be important in this case. It means « why should we write this deviation? ». For this non-conformity, which is major/critical (a risk of recalled batches is widely recognized), it is necessary to raise a deviation in order to track the situation and solve it.

What is the advantage? The use of « 5W + 2H» allows to create a frame for the originator to describe a deviation in a structured way. Finally, the company has a clear view on the problematic and all the necessary information, in order to define:

- Immediate actions to put in place,

- If the production can continue or not (preliminary estimation of quality impact),

- The investigation to put in place,

- The root cause,

- Involved and concerned people,

- Corrective actions and preventive actions plan for solving the problem and avoiding reoccurrence,

The use of « 5W+2H » is not mandatory, nor apparent in the daily workload of a quality engineer. However, it could be interesting to know how to appropriate for yourself and use it in that case. Quality is a field which rhymes with rigor. Especially about the study of non-conformities. It is essential to have all the relevant information in order to work on a deviation, its correction and its prevention.